Quality assessment and defect inspection of transportation infrastructures such as roads, highways and bridges, is required for proper maintenance purpose. Currently, it is mainly done by manual checking, the condition is recorded on paper which later is put into a database. The entire process is very time-consuming and the accuracy level may not be satisfactory.

Evolution Led by Trained AI Model

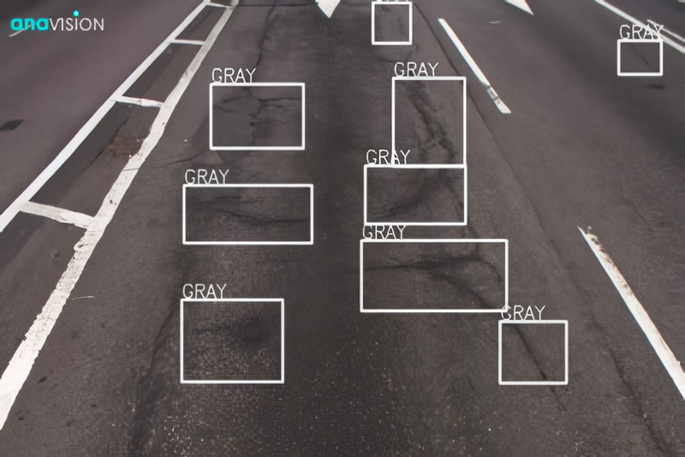

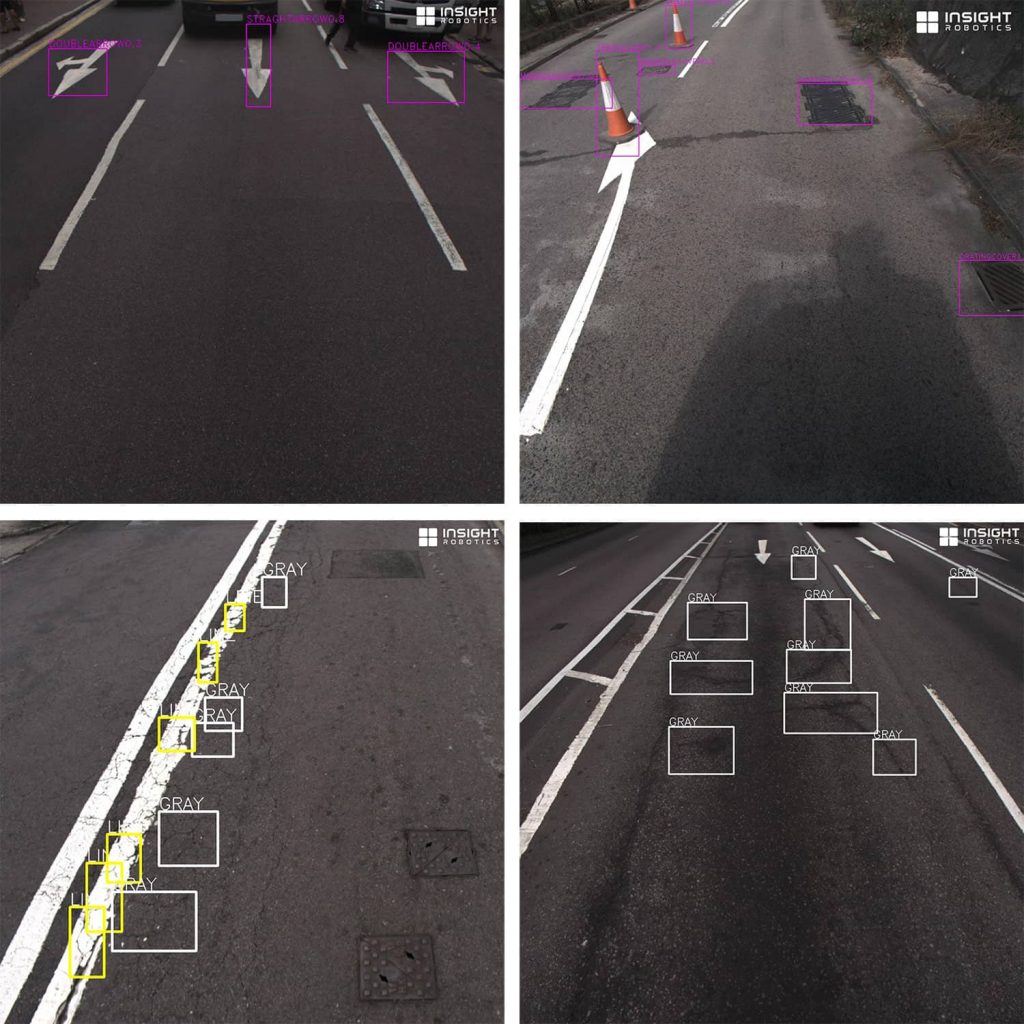

Anavision has developed an intelligent integrated survey solution that determines the type, extent, and location of objects, and damages on the road for our business partner – Insight Robotics. Prior to building the deep machine learning model, we captured training data sets by mounting a camera on the car. Trained AI model with computer vision is capable of detecting:

- Signages / Objects (e.g. traffic cone, manhole cover, crating cover)

- Issues (e.g. blocked crating cover, broken or sunken manhole cover)

- Defects / Damages (e.g. cracks, potholes, decolored signages)

The trained AI model can achieve >93% detection accuracy. It also helps save up to 75% of manual inspection time and reduce the inspection cost by >50%.

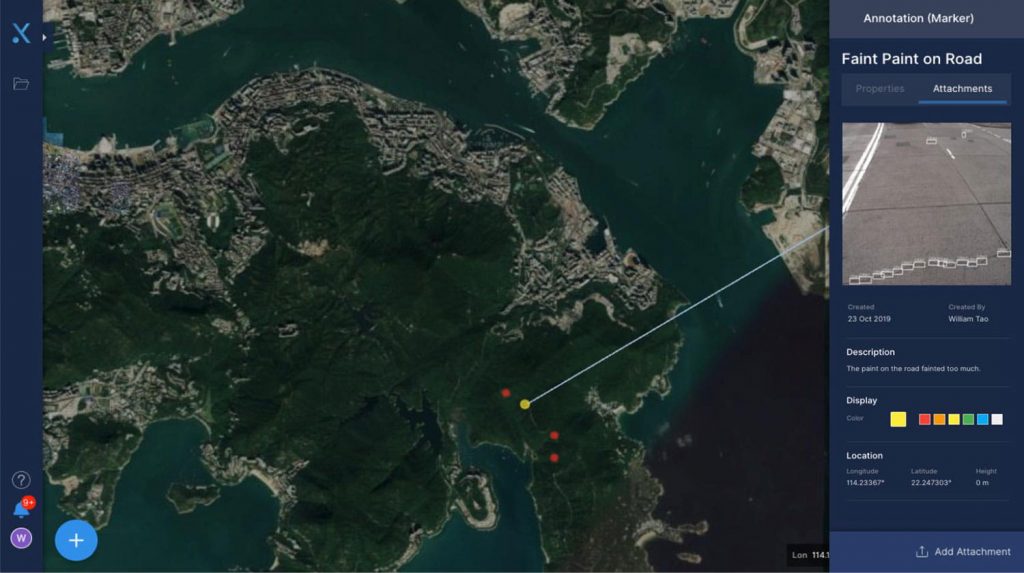

Based on the inspector’s geo-location, all detected issues and damages will be stored, analyzed, and visualized in our map-based user interface platform. Combined with the historical data, our solution can predict the deterioration rate of roads and accessories, assisting road authorities to streamline maintenance workflow.

In conclusion, this intelligent survey can regularly monitor the road surface so that damages like potholes and broken cover can be detected as soon as they occur. In addition, detection of precursor signs like cracks will allow the maintenance crews to address problem areas before they develop into serious problems. Together with semantic segmentation technology, we believe that more interesting and comprehensive inspections can be done in the future.

Want to Learn More?

Check out our Smart Inspection Services for Road Maintenance today.