Solar energy is one of the fastest-growing renewable energy sources. The continuous growth of the solar industry has led to an ever-expanding number of solar installations. Solar power plants are large in scale and a failure-free operation is crucial for efficient energy production of the solar panels. Prior to the construction of the large solar plants, a detailed plan should be made to maximise the usage of space and ensure a seamless operation flow. There is an increasing number of solar companies looking for new ways to streamline workflows and generate actionable insights using technologies.

Incorporating Drones Into Solar Industry

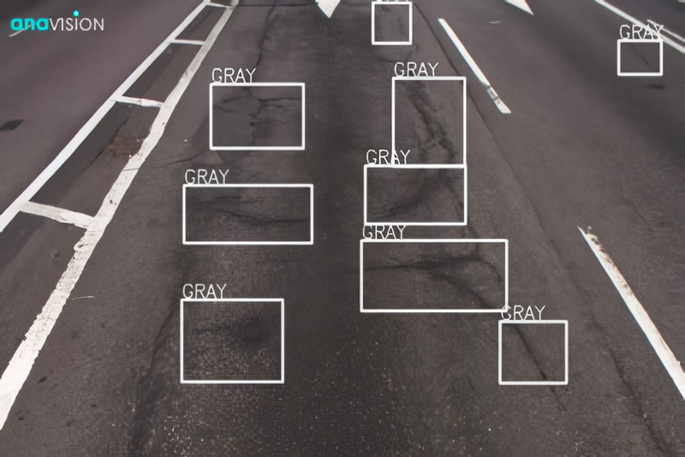

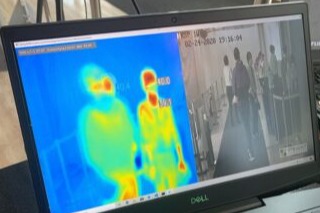

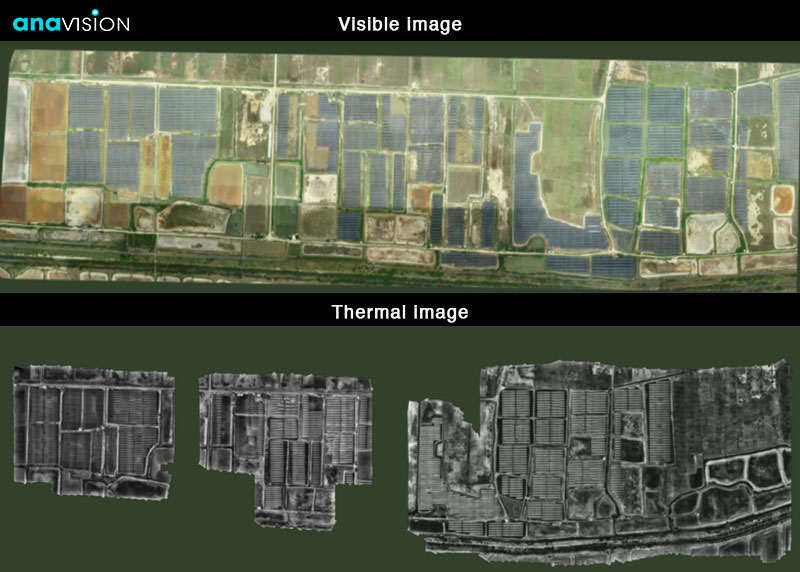

In order to ensure effective deployment and enhance operations of solar systems, Intelligent Inspection of solar panels with visible and thermal drone imagery is a fast, simple, and reliable way to improve safety and efficiency – A drone equipped with appropriate visible and thermal cameras is capable to scan the solar power plant from a bird’s view in real-time, generate high-resolution drone mapping for detecting and identifying different defects such as panel surface stains, cracks, tree blockage, heat unevenness, etc. Drones can also access difficult-to-reach places and shorten the time it takes to find defective solar panels.

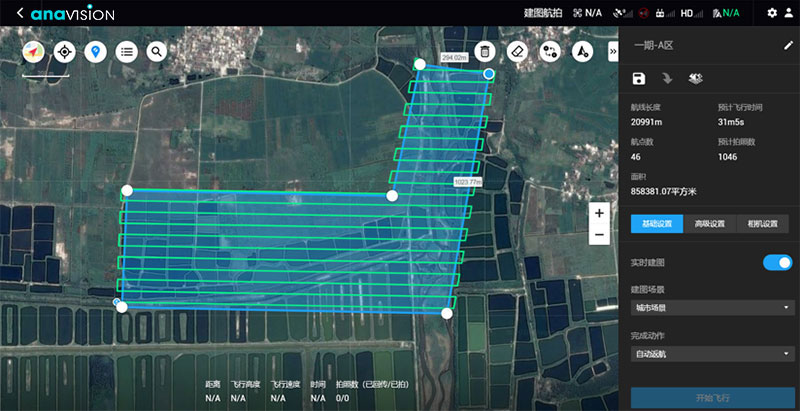

A flight route will be set according to the requirements and environment of the designated site. The drone will then automatically capture images and complete data collection.

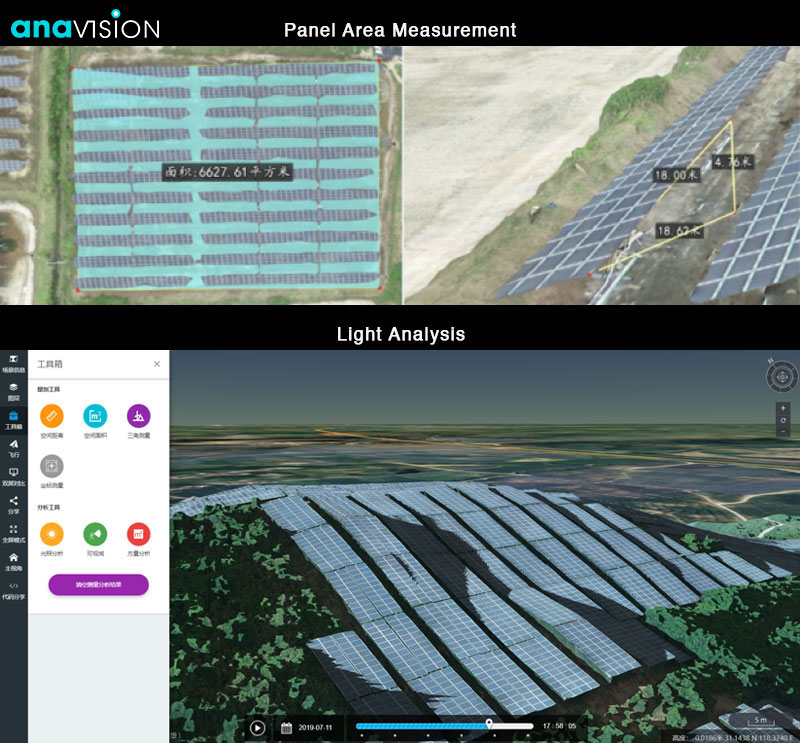

All captured images can be imported into an in-house developed GIS-cased online management platform. They will then be processed using high-speed image stitching. High-resolution 2D/3D mappings will be generated for further measurement and analysis.

Combined with various viewing methods and measurement tools, information can be synchronized and shared with stakeholders, greatly reducing communication costs and improving the solar industry’s productivity.

A detailed inspection report is available for better decision making and site planning.

- Overall panel quantity, area measurement, and defect rate

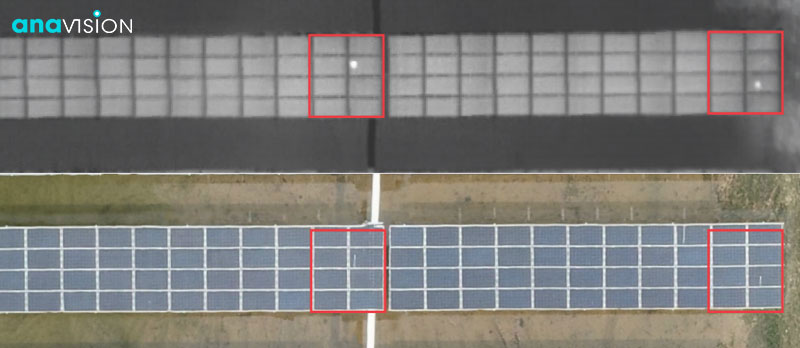

- Visible image for detecting defect/color unevenness, while Thermal imaging for identifying hot spot/heat unevenness

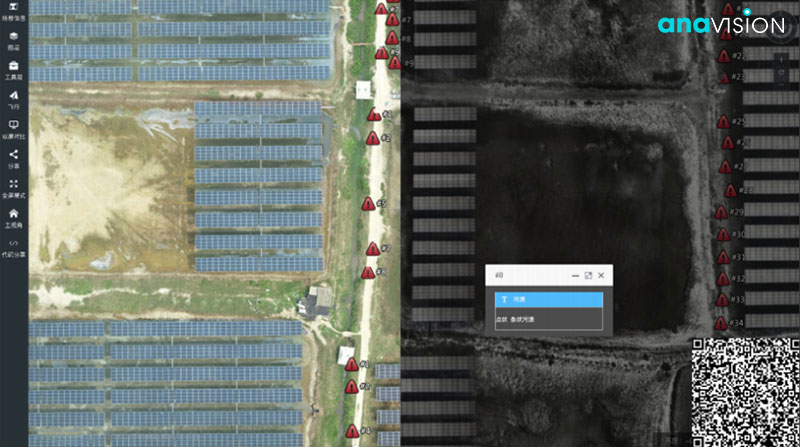

- Inspection for failure zone and defective area

Anavision can conduct inspection from the air in a fraction of time and provide in-depth analysis through high-resolution 2D and 3D maps. Since the solar industry is growing, we believe that intelligent surveys with drone mapping can advance the industry in a cost- and time-effective manner.

Want to Learn More?

Check out our Solar Panel Inspection Services today.